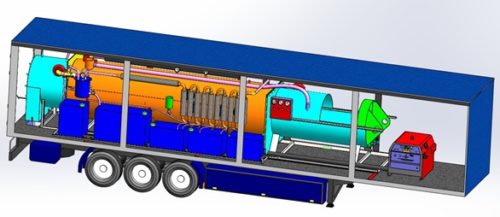

Mobile Depolymerization Technology

The thermal decomposition machine changes the organic material that is introduced into the machine in a solid state to lower hydrocarbons. By organic material is meant predominantly organic compounds, which usually contain inorganic compounds (steel cord) for tires. Under the temperature range of 400 ° C to 500 ° C and without air access, the thermal stability limit of organic materials is exceeded, resulting in the splitting and splitting of macromolecular organic substances to stable low molecular weight products – oil, gas and solid residue.

The resulting thermal decomposition gaseous products are fed to the cooling mechanism and divided into gaseous and liquid fractions. This aerosol blend undergoes several stages of filtration and condensation.

The gases not condensed in the last stage are used as fuel inside the reactor. LTO or other oil suitable for the burner is used to start the plant and is used as fuel for the burner at the time of gas generation.